The Spartan Locker, USA Standard Gear’s lunchbox locker, provides game-changing traction at a low cost. A locker physically joins the drive axles together so they deliver an equal amount of torque to each tire, regardless of available traction. Lockers come in two flavors… selectable or mechanical.

What are the Different Types of Lockers?

A selectable locker is an on-demand unit that the driver activates electronically or pneumatically via a cockpit-mounted button. A mechanical locker is always active, providing traction 24/7. The Spartan Locker and Yukon Grizzly Locker are mechanical. The Yukon Zip Locker is an air locker or selectable locker that uses a pneumatic system for actuation.

In mechanical lockers, also called automatic lockers, on-throttle driving conditions, where load is applied to the differential, induces locking. Off-throttle situations, where the diff is unloaded, leads to a partially unlocked unit. When the vehicle turns and the two wheels on the axle turn at different speeds, the unit makes a clicking sound as the square-cut side gears move over and past one another. This ratcheting sound can be loud and is why mechanical units may not be best suited for vehicles that spend a lot of time on the street… it all depends on how sensitive your ears are.

What’s for Lunch?

The lunchbox locker name is a loose reference to that handy mid-day meal carrier we all know and love. Just as you can put a different kind of meal in your lunchbox, the lunchbox locker allows different internals to be put in your differential… the internals being the lunch and the differential carrier being the box portion of the equation.

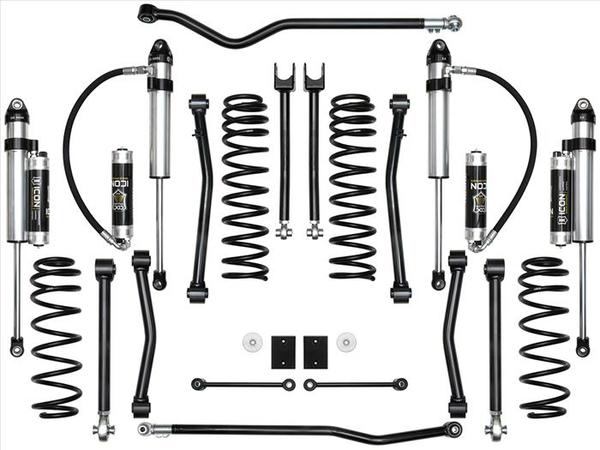

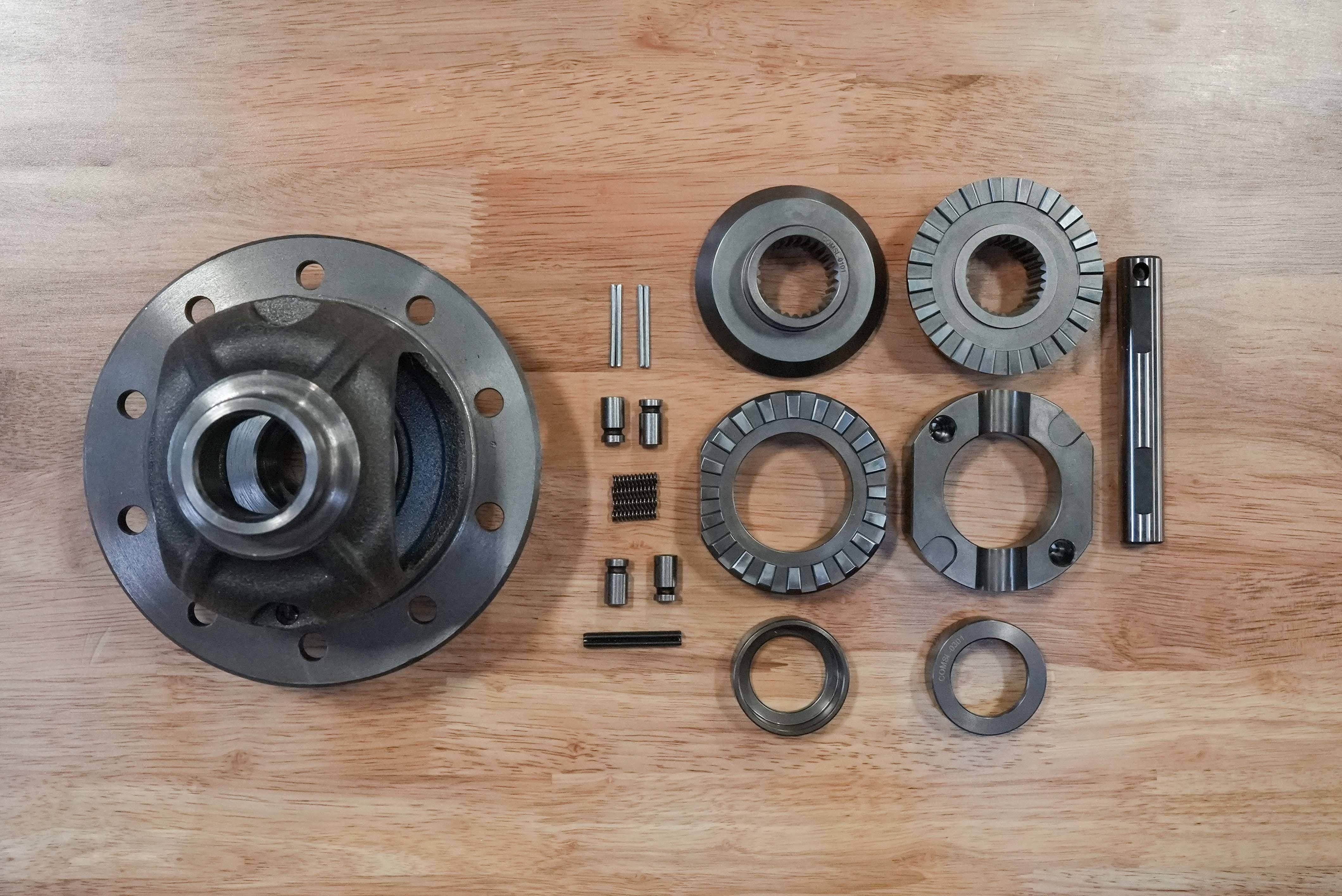

Lunchbox lockers are not a singular component you swap in, but a collection of parts that converts an open differential carrier (and only an open differential carrier) into a mechanical locker. A typical Spartan Locker consists of a pair of drivers, two spacers, two side couplers, four alignment pins, four pre-load springs, a hardened cross-pin shaft, a roll pin, and installation wires. Depending on the differential carrier design, your Spartan Locker could have more or less components in the box.

Lunchbox lockers are not a singular component you swap in, but a collection of parts that converts an open differential carrier (and only an open differential carrier) into a mechanical locker. A typical Spartan Locker consists of a pair of drivers, two spacers, two side couplers, four alignment pins, four pre-load springs, a hardened cross-pin shaft, a roll pin, and installation wires. Depending on the differential carrier design, your Spartan Locker could have more or less components in the box.

Pros and Cons of Lunchbox Lockers

Great grip on a budget is the lunchbox locker’s calling card. Price is the biggest pro for the lunchbox locker. They cost less than half the price of an air locker, and remember this is before factoring in the cost of a pneumatic operating system. The lunchbox locker is about a third of the price of a large-frame mechanical locker / automatic locker. Going with a lunchbox locker also pays off when it comes to installation. Since the process is less labor intensive than a large-frame locker installing a lunchbox locker costs less. The savings can be even more substantial if you handle the install yourself.

The Spartan Locker's patent-pending design replaces the spider gears in a standard carrier case, does not use the thrust washers, and has a revolutionary spring-and-pin design that makes installation quick, easy, and much cheaper that other types of lockers! Further, in some cases, the install does not require the removal of the differential. A disadvantage of this is the lunchbox locker relies on the factory carrier for strength. Large-frame lockers, like the Grizzly and Zip, replace the carrier as a single unit and their case is constructed from a much stronger alloy steel compared to the factory carrier. Being locked all the time, mechanical lockers can cause accelerated tire wear. As with many modifications, it’s a game of trade-offs.

Installation Tips and Tricks

If you’re able to remove the spider gears with the carrier still in the housing the installation can be done without removing the .png) carrier from the diff. If it’s too tight in there, the diff will have to be removed. Spartan Lockers come with a highly detailed installation manual that includes tons of photos and step-by-step instructions. The manual addresses installation in a variety of differentials. Basically, the Spartan Locker’s drivers are assembled with the alignment pins and springs installed. The installation wires keep the assembled unit together until installation is finalized then they’re removed releasing the spring tension that’s needed to operate the unit properly.

carrier from the diff. If it’s too tight in there, the diff will have to be removed. Spartan Lockers come with a highly detailed installation manual that includes tons of photos and step-by-step instructions. The manual addresses installation in a variety of differentials. Basically, the Spartan Locker’s drivers are assembled with the alignment pins and springs installed. The installation wires keep the assembled unit together until installation is finalized then they’re removed releasing the spring tension that’s needed to operate the unit properly.

Spartan Locker Installation Quick Tips

- For Use in Open Differentials Only

- Remember to Re-Install Carrier Shims and Bearing Caps in the Same Place

- Punch Mark Bearing Caps to Indicate Which Side to Install Them On

- Be Sure Tires are Same Circumference to Ensure Proper Locker Engagement

Are Lunchbox Lockers for You?

Vehicle usage is the tipping point. Not just how much your rig will see the street where the boisterous operation of the lunchbox locker comes into play but off-road usage as well. Your expectations on the trail; and how much you’ll be demanding from the driveline come into play. If you’re staying on the trail with moderate hill climbing, scrambling over rocks, and the like, the lunchbox is a good call. If you plan to be more aggressive and looking to get into some extreme situations where a great deal of torque and load shocking are the norm, a large-frame locker may be the way to go. When it comes to the ratcheting and clunking sounds the unit makes, read up on the subject. Some users report the sound isn’t that intrusive, others say the noise fades with use. As we indicated before, the performance game is made of trade-offs… but the payoff is big.

Spartan Locker Highlights

- Big on Traction, Low on Cost

- For Use in Open Differentials Only

- Patent Pending Design Replaces Spider Gears

- Low-Cost Shop Installation - Can be DIY Installed

- Reliable 100% Lockup Power Transfer

- Features Heat-Treated 9310 Steel Internals for Enhanced Durability

or contact us at 866-631-0196

AMC

AMC

Chrysler

Chrysler

Dana

Dana

Ford

Ford

GM

GM

Isuzu

Isuzu

Nissan

Nissan

Suzuki

Suzuki

Toyota

Toyota