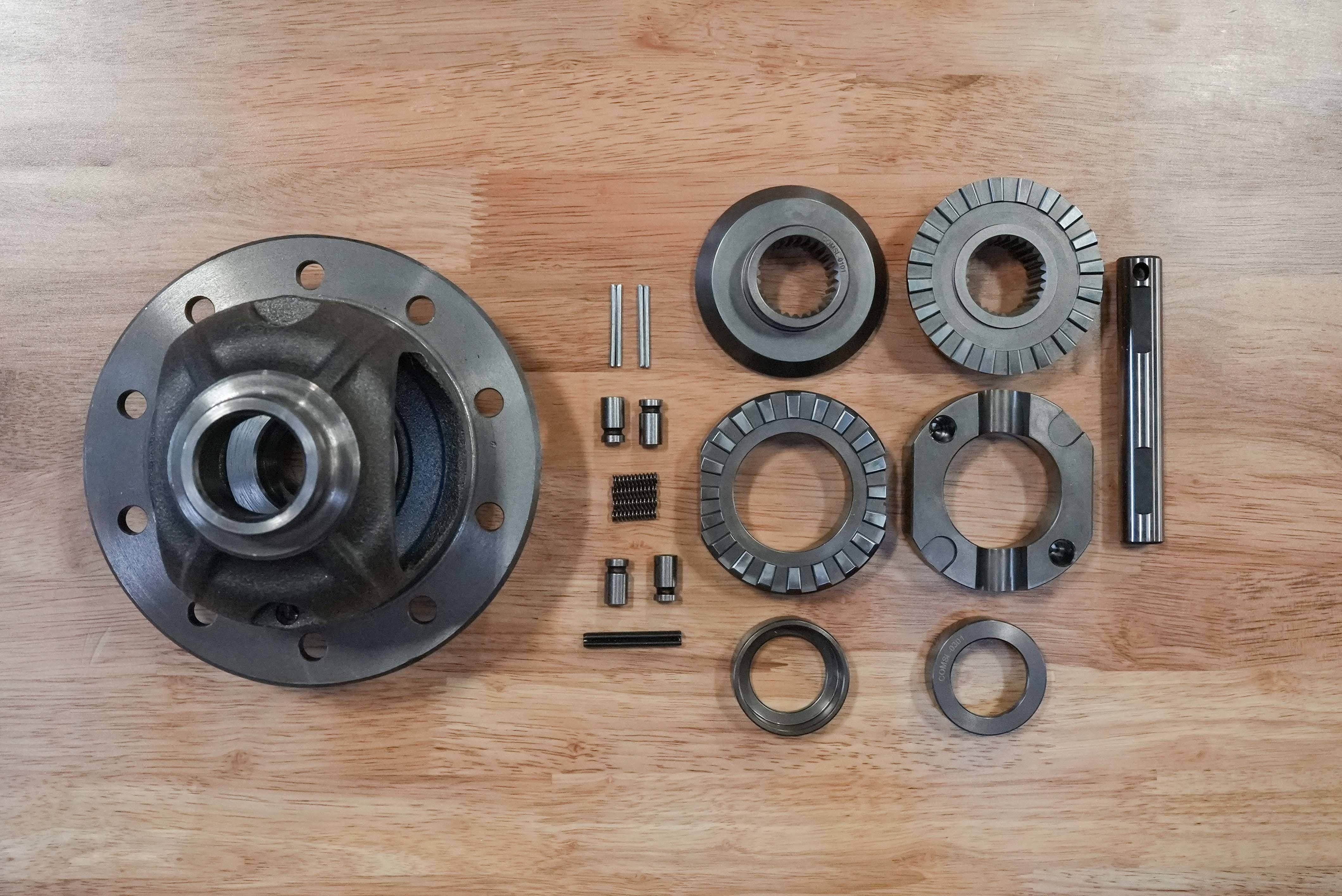

Gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Pulling off a proper differential setup comes down to precise adjustments. Parameters like pinion depth, backlash, pinion-bearing preload, and carrier-bearing preload allow you to fine tune the relationship between gear teeth to ensure proper meshing and ultimate durability.

Checking the Pattern

We can determine how gears mesh by changing how close the pinion gear is to the ring gear centerline. While we can’t physically see how the gears actually relate to each other, we can coat their mating surfaces with gear-marking compound and read the patterns the gears create as they mesh. Genuine gear-marking compound offers a clear indication of gear contact without running or smearing. Anything other than gear marking compound (such as blue machinist dye) will not give a clear indication of tooth contact. Dilute the marking compound with a small amount of oil if necessary to create a smooth, but not runny, paste. Coat three or four ring-gear teeth in at least two places with a moderate amount of compound and rotate the ring gear around the pinion gear four or five times in both directions. Rotate by grabbing and turning the ring gear, not the pinion. Pinion resistance against the rotating ring gear helps establish a good pattern. Pinion bearing preload usually provides enough resistance for a good pattern, but additional resistance can be added by wrapping a shop towel around the yoke and pulling the two ends tight.

An alternative method for checking gear patterns in cases where reading the pattern is difficult involves spinning the pinion. Paint three or four ring gear teeth as usual on both coast and drive sides of the teeth. Using a ½” drive adapter on a hand drill (not on an impact gun/driver) spin the pinion for 30 to 60 seconds in each direction while applying drag to the edge of the ring gear. Not only does this typically produce a clear, well defined pattern on the painted teeth, but it creates a negative or “ghost” pattern on the non-painted teeth that may provide additional insight to the pattern, while also conveniently showing any potential run out issues (where the pattern is shifting from heel to toe as the gear is rotated). This technique also helps to minimize diagonal striping in the pattern that occurs when rocking the gears back and forth, which can lead to misdiagnosed patterns. The down side of this method is more cleanup between adjustments to remove the compound but the additional data is well worth the effort.

Here is a good example of the alternate technique. You can see on the bottom couple of teeth that were painted how the compound got smeared resulting in diagonal striping, and hard to read, as opposed to the “ghost” or negative patterns on the non-painted teeth being quite clear and well defined.

Anatomy Of A Gear Tooth

The pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe (ring gear inside diameter). Gear patterns change from heel to toe, but in most cases an ideal heel-to-toe pattern is impossible to achieve. Furthermore, the housing itself influences the heel-to-toe pattern and the pattern cannot be changed without machine work. Trying to obtain a pattern centered exactly between the heel and toe usually leads to frustration and a noisy gear set if the face to flank pattern is not correct. Instead, concentrate only on the position of the pattern and how it relates from face to flank of the ring gear teeth.

Cause, Effect, Action

A contact pattern centered from face to flank indicates the correct pinion depth.

A contact pattern closer to the gear face means the pinion is too far away from the ring gear. To correct the pattern, move the pinion toward the ring gear centerline.

A contact pattern closer to the gear flank means the pinion is too close to the ring gear. To correct the pattern, move the pinion away from the ring gear centerline.

1. Use shims to move the ring gear closer to the pinion gear to decrease backlash.

2. Use shims to move the ring gear farther from the pinion gear to increase backlash.

3. Use shims to move the pinion closer to the ring gear to move the drive pattern deeper on the tooth (flank contact) and slightly toward the toe. The coast pattern will move deeper on the tooth and slightly toward the heel.

4. Use shims to move the pinion further away from the ring gear to move the drive pattern toward the top of the tooth (face) and slightly toward the heel. The coast pattern will move toward the top of the tooth and slightly toward the toe.

Make Large Pinion Depth Adjustments First

When changing the pinion depth, make large changes until the pattern is close to ideal. Consider 0.005” to 0.015” a large change and 0.002” to 0.004” a small change. Intentionally, make adjustments that move the pinion too far at first. If the pinion moves too far and the pattern changes from one extreme to the other, the correct pattern lies somewhere between the two adjustments. Once you get close to the correct pinion depth, make smaller changes until the pattern centers between the face and the flank of the ring gear teeth. Once the backlash and pinion depth meet tolerances, remove the carrier and establish the final pinion bearing preload.

AMC

AMC

Chrysler

Chrysler

Dana

Dana

Ford

Ford

GM

GM

Isuzu

Isuzu

Nissan

Nissan

Suzuki

Suzuki

Toyota

Toyota