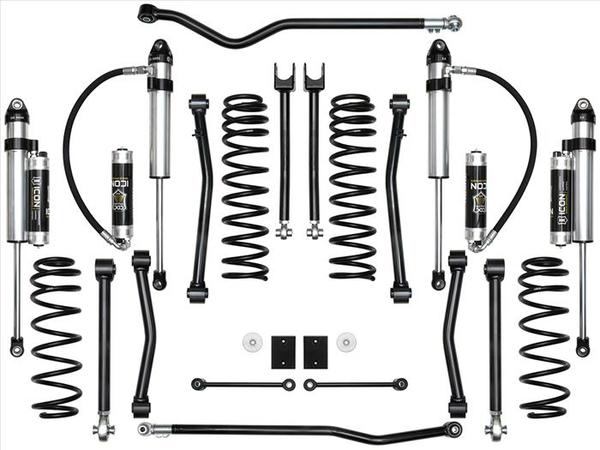

When the JL platform hit the trails in 2018 it was quickly embraced by Jeep enthusiasts and most of these Jeep fans were soon on the warpath for performance parts. Like every other Jeep platform, opportunities for aftermarket manufacturers to modify, lift, and accessorize were in wide and varied. In fact, parts were in the pipelines before the JLs were dropped off at dealerships.

Jeep’s New Differentials

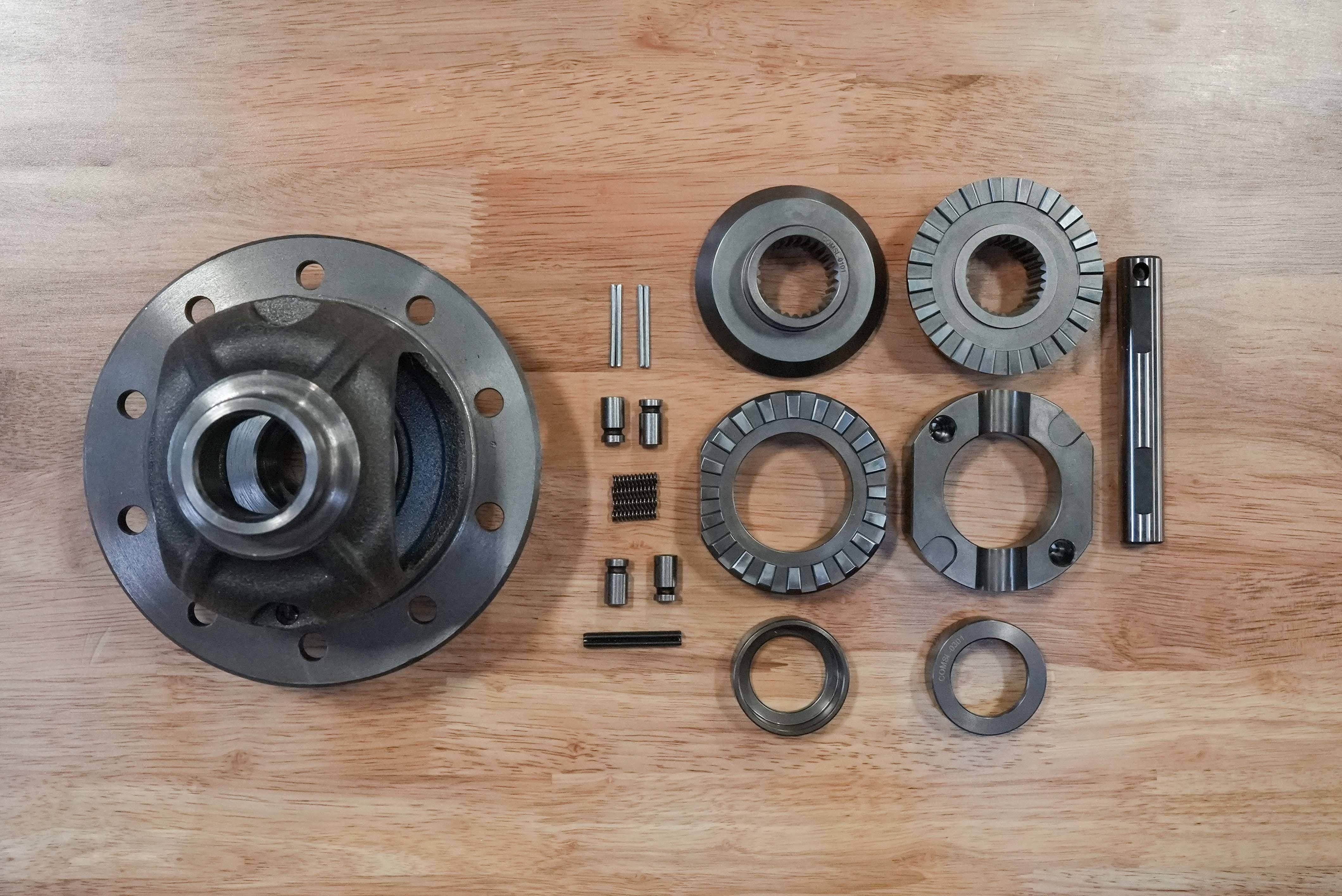

Aftermarket drivetrain engineers working on the new Jeep JL platform were met with a number with design challenges when it came to the ring and pinion gears. The JL launched with a new set of differentials including the D44JL Rear (M220), D44JL Front (M210), and D35JL (M200). Factory engineers designed the ring and pinions for higher efficiencies. Whether this had to do with the JL’s front axle disconnect feature for increased fuel mileage or other powertrain revisions, differential upgrading needed extra engineering focus.

Superior Engineering

From a design perspective, this factory revision denotes a decrease in the hypoid offset compared to previous JK designs, resulting in a smaller pinion head diameter with increased loading on the teeth. Most aftermarket manufacturers recognized the design change... that was the easy part. Only Yukon noticed that the design change required improvements to the metallurgy as well. Stronger alloys, most notably an increase in the nickel content, were required to handle the additional loads.

Superior Metallurgy

Diagnosing the significant changes in the OE gears for the JL platform, our team of engineers examined countless material and heat treatment options to effectively address the new hypoid offset. Yukon realized the need to manufacture the JL ring and pinion line with a premium higher strength 4320 material to hold up to the abuse and provide even higher strength than the JK. After testing Yukon against other aftermarket brands, it appeared we were the only aftermarket company to move to higher strength material and produce the strongest aftermarket gears associated with the Jeep JL line.

*An increase in the Nickel content (Ni) provides higher tensile and yield strength and improved impact properties.

**Aftermarket competitors benchmarked for JL gears show use of lower Nickel (Ni) materials.

***Tensile and Yield strengths are approximate

Providing top-of-the-line drivetrain products has been the goal of Yukon Gear & Axle from Day One. Yukon quality labs and engineers go the extra mile to provide you with a product that can be trusted no matter how sketchy the terrain gets. Yukon’s selection of products from gears, traction devices, driveshafts, kits, and covers to name a few, are the highest quality in the industry and we continue to exceed industry standards so you can wheel with confidence.

AMC

AMC

Chrysler

Chrysler

Dana

Dana

Ford

Ford

GM

GM

Isuzu

Isuzu

Nissan

Nissan

Suzuki

Suzuki

Toyota

Toyota