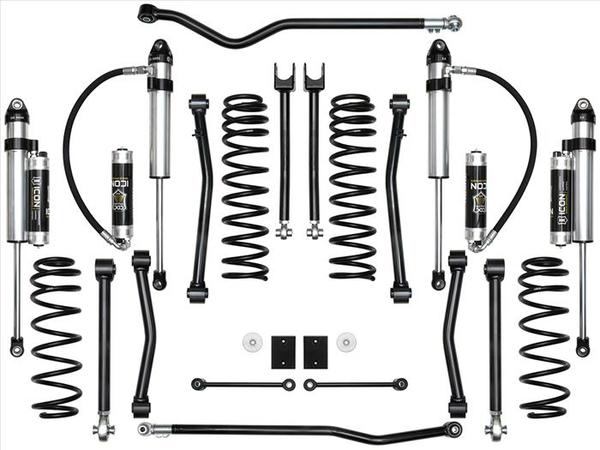

This edition of Tales From The Tech Line illustrates what happens when someone sets their grinder to overkill. The fiasco starts with a Toyota Land Cruiser moving up to a 4.56:1 gear that requires a little extra installation effort. That’s right your TLC will need some TLC if you plan to run a 4.56 or deeper gear set. The catch? The Land Cruiser diff sports semi float axles that use C-clips which makes removing the cross-pin problematic as there is an interference issue. In this case, minor clearancing of gear teeth is needed in order to remove the cross-pin and facilitate the gear swap. Gear grinding is not an unheard-of occurrence. There are right and wrong ways to do this.

Under the banner of ‘Wrong Way’ we present this TLC diff that happened to be upgraded with a Yukon Grizzly Locker. It should be noted that the locker played no role in the clearance issue. This is a strictly ring gear meets cross-pin affair. A total of eight teeth had material removed, four of them had roughly half the tooth cut away, the carnage protruding well into the contact pattern.

.jpg)

Above you can see a very significant amount of grinding was done, all the way to the root of the teeth. This overkill results in severely compromised ring-gear-to-pinion contact on an extended area of the gear dooming the ring gear to a high probability of failure even under light load.

.jpg)

.jpg)

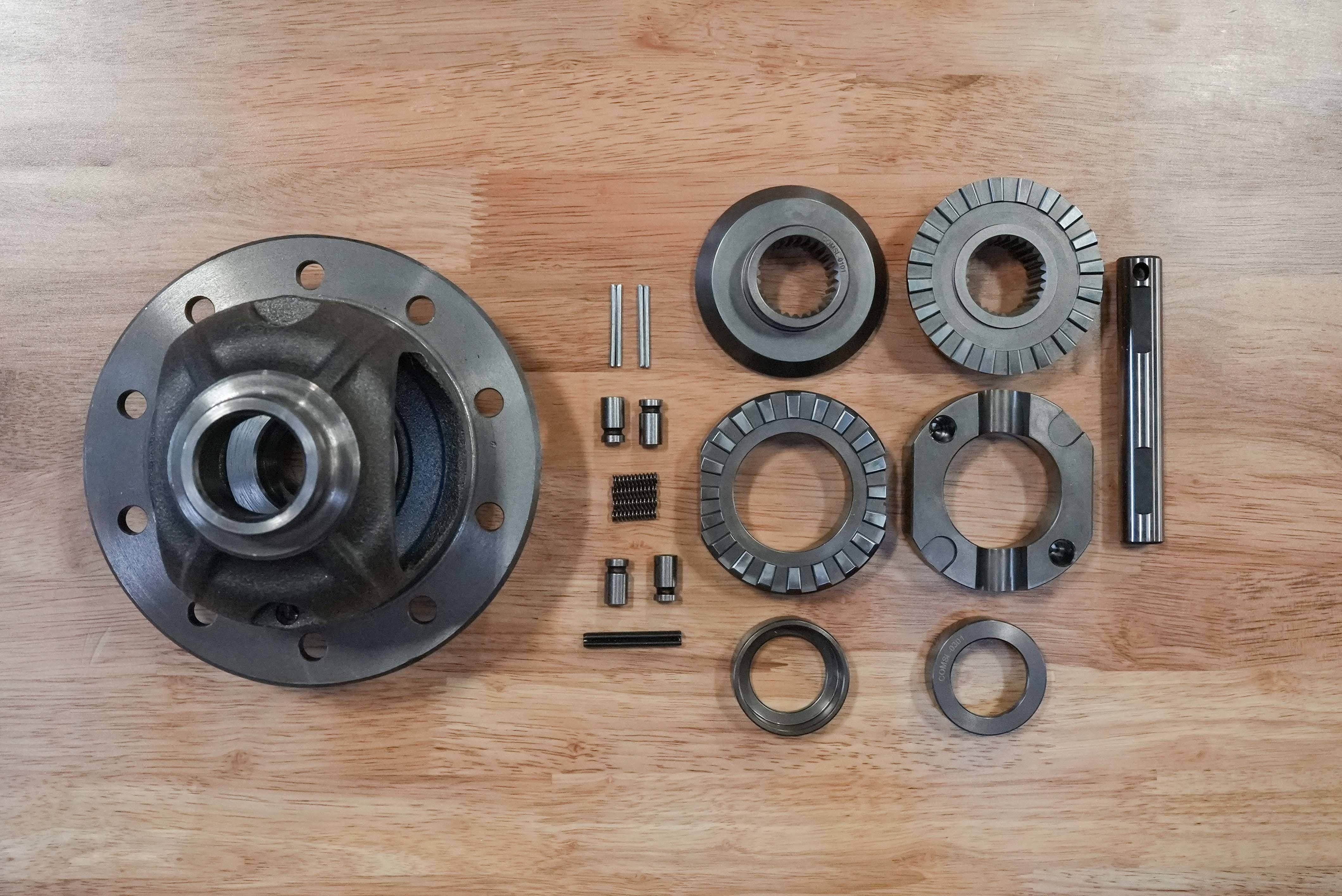

Above you can see a new gear set installed on the carrier, and light contact being made on just the tips of two teeth.

The right way to do this is to removed as little material as possible, just enough to get the cross-pin out. Note the small area of contact marked with a paint pen prior to grinding. This keeps the procedure manageable.

Grinding was easily executed in less than five minutes with a Dremel and a sanding roll. The amount of material removed was an area about the size of a typical pencil eraser and a smaller amount primarily on the top face on one tooth and knocking the corner off the second tooth.

Viewed from the end, you can see how little material was removed. Note all grinding should be done with the gear on your workbench, not installed in the housing where shards can contaminate the gears.

The minor clearance required was completely outside the tooth contact pattern and resulted in no loss of gear strength.

Shop Ring And Pinion Gear Sets

AMC

AMC

Chrysler

Chrysler

Dana

Dana

Ford

Ford

GM

GM

Isuzu

Isuzu

Nissan

Nissan

Suzuki

Suzuki

Toyota

Toyota